On a daily basis, public works and municipal employees report to the streets to maintain our country’s critical infrastructure. In the course of doing their jobs, they contend with a variety of traffic risks, biohazards, hazards within confined spaces, and the dangers of excavating and trenching. Safety protocols have been established to protect these employees.

Want to keep safety and best practices in view at all times? Check out our FREE Safety Poster Pack. It has three safety posters that cover health and hygiene, traffic safety and confined space entry.

The Federal Highway Administration reports that in 2015, a work zone crash occurred once every 5.4 minutes. Taking extra precautions to make these zones compliant with traffic safety regulations is the best way to minimize risk.

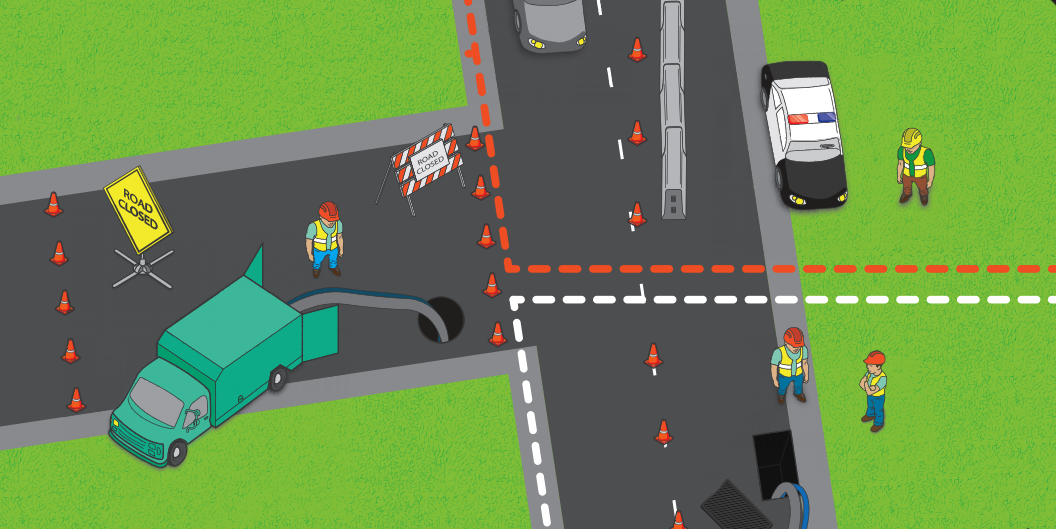

In order to protect workers and comply with the law, the following steps should always be taken before beginning sewer work:

During a temporary traffic control (TTC) zone, road traffic procedures are changed because of utility work activities. It is typically marked by signs, channelizing devices, barriers, pavement markings or work vehicles.

Most TTC zones are divided into four areas:

One of the most effective ways to increase worksite safety is properly warning motorists of the upcoming work. Alerting drivers to changes in the normal flow of traffic will allow them to better prepare for entering and passing through the work zone safely. Signs, electronic reader boards or sign cars with lights are used to notify drivers of what to expect.

Different speed zones require different signage to be effective. In high and moderate speed zones, multiple signs should be placed so they are not overlooked. These signs notify motorists about upcoming road work, speed reductions or lane merges that will affect them.

After the advanced warning area, a transition area using cones and barriers can help smoothly merge traffic into fewer lanes leading up to the road work zone.

The actual work zone, also commonly referred to as the

After the work zone, “end road work” signs may be used to signal a return to normal traffic flow.

To learn more about warning sign placement and TTC zones, request Envirosight’s Traffic Safety Poster. Ready to test your traffic safety chops? Take our Sewer IQ: Traffic Safety Quiz.

For the average person, regular hand-washing and use of hand sanitizer, as well as keeping up with vaccinations, is sufficient to stay healthy. For those who work in the medical field or around sewers, there is an increased risk of infection and disease due to biohazard exposure. Much like doctors and nurses take extra care to limit that exposure, wastewater workers should also take extra precautions.

Wastewater and its treatment can generate aerosols containing microbiological and chemical constituents. Wastewater workers run the risk of exposure to both waterborne and airborne disease organisms. As a result, sewer workers can easily and unknowingly interact with biohazards through inhalation and skin contact. Some hazards that workers can be exposed to include:

Want to learn more sewer worker health and hygiene? Request Envirosight’s Health and Hygiene Poster. Ready to test your health and hygiene chops? Take our Sewer IQ: Health & Hygiene Quiz.

The Center for Disease Control recommends getting vaccinated against these various diseases if you work near sewers:

This list is not exhaustive. Other parasites found in sewers include salmonella, yersiniosis, encephalitis and many more. Most of these illnesses can be treated, but it involves hospitalization and antibiotics. Polio has no treatment. Getting vaccinated helps avoid a painful illness and it’s recommended that sewer workers discuss their options with a licensed medical practitioner.

Wearing personal protective equipment (PPE) is a proactive way to guard against any harmful biohazards a sewer worker may come into contact with. The most significant step a wastewater worker can take towards protecting their health is to use adequate PPE. The better your PPE, the less likely you are to contract a disease or infection from sewage. Recommended items for working around sewers are:

While this equipment helps protect sewer workers from exposure to biohazards, it can only be effective when used properly and consistently.

It is important to make sure the

The last thing anyone wants is for the people they love to get sick. To prevent that, shower and disinfect yourself before returning home, and never take your work clothes or shoes home. Those items can easily be cleaned on-site or laundered professionally and keep work contaminants far away from the home.

At the end of the day, there is a simple list of do’s and don’ts that can keep you safer and healthier:

Make sure to:

And don’t:

Want to learn more about health and hygiene best practices? Request Envirosight’s Health and Hygiene Poster. Ready to test your health and hygiene chops? Take our Sewer IQ: Health & Hygiene Quiz.

According to data from the U.S. Bureau of Labor Statistics, an average of 50 workers

According to OSHA, a confined space:

There are three primary categories for confined space hazards:

All of these hazards can be controlled and avoided through proper procedure and personal protection equipment.

Sometimes entering a confined space is unavoidable. During those times there are a few things you can do to ensure your safety.

For a confined space to require a permit, it needs to have only one of the following traits:

By definition, a permit-required confined space presents more hazards and potential risks for sewer workers. Before even considering working in one of these confined spaces, it’s necessary to first undergo permit-required confined space (PRCS) certification training. If a worker is already certified to enter the confined space then it is still necessary for the supervisor to obtain the required permit. It’s important to note that this permit isn’t just a formality, it contains all of the necessary information regarding the potential dangers and recommended safety protocols. Simply obtaining a permit is not enough, it is vital to the safety of the sewer worker that the permit is read and obeyed.

Remember, never enter a confined space alone. It’s always necessary to station an attendant above ground to observe the operation. In the event of an emergency, an attendant can be the difference between life and death for a sewer worker in a confined space. Be sure that the attendant is equally informed about confined space hazards so they are aware of what specific hazards to monitor for, as well as what the evacuation procedure is.

In addition to standard personal protective equipment (PPE) such as: face/eye protection, hard hats, steel-toed boots and gloves, be sure to use:

Ensure the gas concentrations are within safe levels before entering the confined space and continue to monitor levels throughout to ensure safety. Protect yourself by always wearing a personal gas monitor that measures for:

Workers should never enter deteriorated structures or cavities with high flow or loose soil, as these have a higher risk of engulfment.

Confined spaces always present risks for sewer workers and the only way to truly avoid these risks is to avoid entering a confined space whenever possible. Before entering a confined space it’s first necessary to perform a complete assessment of all hazards. Be sure to review the proper evacuation procedure and check that the necessary equipment is present and ready for use. Also, it is vital that anyone that enters a confined space has been trained on proper protocol.

In order to minimize personal endangerment, consider conducting your sewer inspection with video sewer inspection equipment. A manhole inspection camera, CCTV sewer inspection crawler, video nozzle and zoom camera provides sewer workers with everything they need to quickly and efficiently complete a sewer inspection without exposing themselves to potentially lethal atmosphere hazards and risks like engulfment and entrapment.

Need a resource to keep you and your crew safe when working in confined spaces? Request Envirosight’s Confined Space Safety poster. Want to test your confined space safety chops? Take our Sewer IQ: Confined Space Safety Quiz.

The U.S. Department of Labor’s Occupational Safety and Health Administration (OSHA) reports

To be safe and compliant with OSHA standards, a “competent” person on your team must be identified. Per OSHA, this individual, “must be capable of identifying existing and predictable hazards, or working conditions that are hazardous, unsanitary or dangerous to employees, and who has authorization to take prompt corrective measures to eliminate or control these hazards and conditions.” Ultimately, the competent person will be responsible for managing the trench site and its workers’ safety and taking action if conditions are subpar.

Inspections must take place daily, prior to work entry of an excavation site, after rainstorms, and as needed throughout shifts or after other hazardous events. The competent individual will need to look for indications of possible cave-ins, failure of protective systems, hazardous atmospheres and other hazardous conditions. Should anything appear wrong, they must be able to take action accordingly.

Inspections should study the soil and protect it accordingly. Soil analysis is to be done by the competent person both visually and manually. Soil type and the appropriate cave-in protection will need to be identified as well. Sloping, trench boxes and shoring are all available methods, but their use should correspond with the right soil type.

It’s easy to fall into a routine, but organizations must play by the rules. Pay special attention to OSHA’s requirements and policies for trenching and excavation safety, such as hiring a registered professional engineer to design trenches at a depth of 20 feet or greater. Stay up to date with standards too, as they are updated regularly. Additionally, even if an employee is not the designated competent person, he or she should still actively monitor the trench and excavation environment for:

Adjacent structures

Learn more about safety procedures of excavating and trenching in the article: Dangers of Digging.