Inflow and infiltration is defined as groundwater and stormwater that enter a sewer system. Collection systems can be damaged when they are forced to transport more flow than they are designed to handle. Increased effluent also raises costs for wastewater treatment facilities, because harmless stormwater and groundwater

Exceeding the capacity of the collection system can result in

Learn more by requesting the training guide: Sewer Maintenance 101: The Quick and Dirty Guide to Sewer Inspection and Upkeep

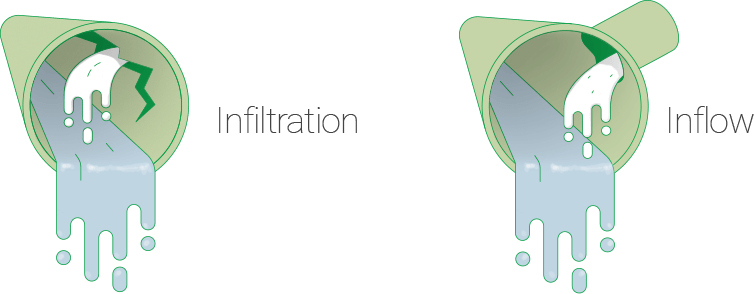

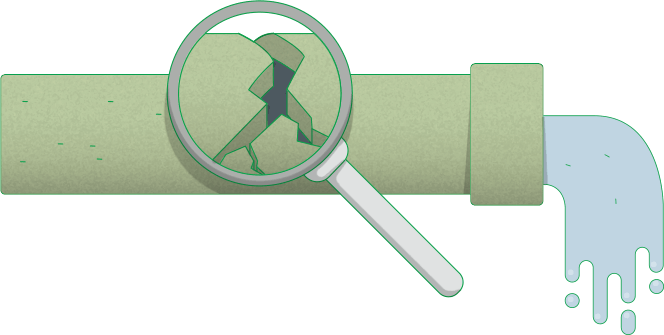

Infiltration occurs when groundwater seeps into sewer pipes through cracks, leaky pipe joints and/or deteriorated manholes.

Inflow is stormwater that enters the sewer system through rain leaders, basement sump pumps or foundation drains illegally connected to the sewer. Together, inflow and infiltration place a burden on collection systems and wastewater treatment facilities.

Learn more by requesting the training guide: Sewer Maintenance 101: The Quick and Dirty Guide to Sewer Inspection and Upkeep

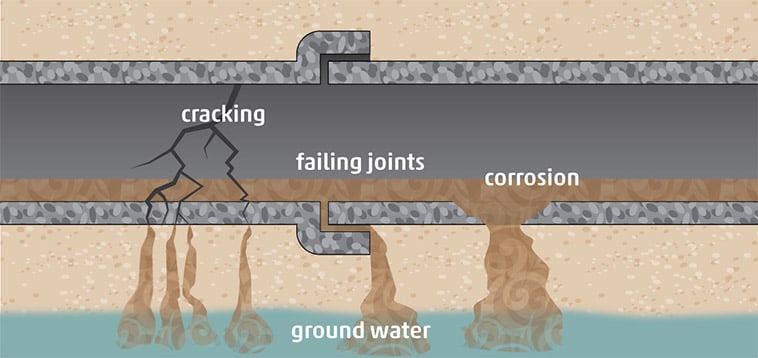

Exfiltration is defined as the leakage of wastewater out of a sanitary sewer system. Exfiltration seeps out of broken or damaged pipes and manholes. Wastewater that leaks from defective pipe joints and cracks may contaminate ground and surface water and nearby water bodies. It can also cause pipe structure failures due to erosion of soil support, and ground subsidence due to erosion of underground soil.

The EPA considers infiltration excessive if a system's average dry weather flow is more than 120 gallons per capita per day. This total includes infiltration, domestic flow, and nominal industrial and commercial flows.

It does not consider regional and seasonal factors like the intensity of precipitation events and varying groundwater levels. For this reason, some states prefer a criterion of gallons per day. An alternate EPA method suggests that system-wide infiltration rates under 1500 gallons per day per inch of diameter per mile of pipe (gpd/idm) are acceptable. The EPA’s inflow benchmark is 275 gallons per capita per day.

Still other standards argue simply that all I&I is excessive, unless it’s too pricey or difficult to eliminate. Whatever the calculation, most operators agree that if a plant experiences overflows during storm events, the inflow is excessive.

Your region may rely on entirely different standards, so staying up to date on the most recent regulations is the only way to avoid fines or government interventions.

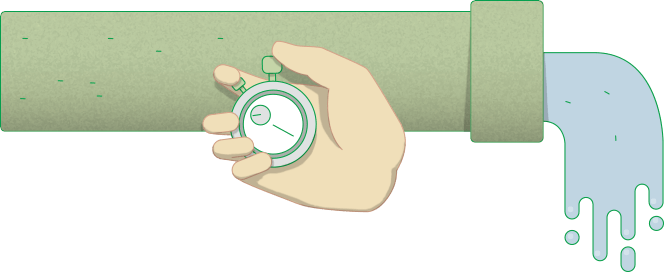

Flow monitoring is the practice of measuring wastewater flow in the system over time and comparing it with a baseline flow estimate. These measurements are used to determine the amount of I&I in the sewer system. Flow monitoring can be used to identify and prioritize areas for further inspection. Visual inspection methods can then determine the severity of I&I in an area. More information on calculating inflow and infiltration can be found in Working Smarter Against I/I.

The FELL-41 is another method to calculate I&I. It involves surcharging a section of pipe with water and then introducing electrical current to identify any potential leaks in the pipe’s wall. The method produces two data points: the amount of electrical leakage (a proxy for water leakage) and the distance within the pipe of the leakage. Learn more about this method's reliability in this white paper.

Making smart decisions about sewer maintenance requires both a quantitative approach (such as FELL-41 and flow monitoring) and a qualitative approach (visual inspection methods) to infiltration. To learn more, read the white paper: Quantitative vs Qualitative: The Case for a Multidimensional Approach to Sewer Condition Assessment.

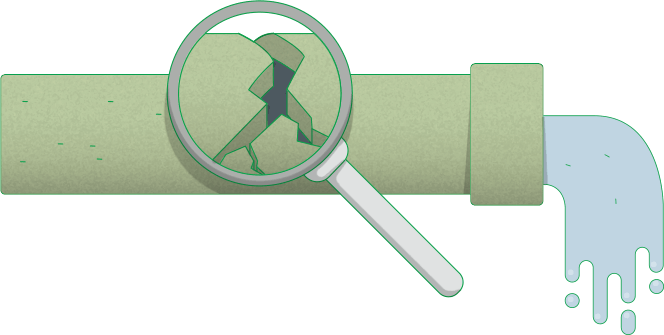

Once target areas have been identified through flow monitoring, municipalities should further inspect for I&I. They can also use their findings to create a plan to combat inflow and infiltration. A comprehensive approach to locating defects involves inspecting all aspects of a collection system, including manholes, sewer mains and laterals.

Manholes generate a disproportionate amount of inflow and infiltration. Field inspectors should evaluate the manhole lid, frame condition and the frame connection for any structural defects or leak sources.

The interior of a manhole can be assessed with a manhole inspection camera or a zoom survey camera (also called a pole camera). Manhole inspection cameras capture both visual and dimensional data points, such as a flat scan with detailed images of the manhole wall and point cloud data for 3D visualization. A zoom camera uses a video camera mounted on a sliding pole. During inspection the operator should note all cracks and deficiencies and decide whether findings are a source of I&I.

Learn more about tackling I&I through manhole inspections here.

Groundwater seeps into sewer pipes through cracks, leaky pipe joints and deteriorated pipes. A CCTV inspection is the most thorough way to find and understand I&I in pipelines. Sewer inspection crawlers use a video camera mounted on a remote-controlled robotic crawler that is connected to a monitor. An operator watching the video can stop to study parts of the pipe to find the specific location and cause of infiltration.

Residential and service laterals often add to I&I, and careful inspection of private connections can help locate overlooked sources of I&I. One study found that 20-25 percent of I&I may be eliminated when service laterals are renewed following sewer lining.

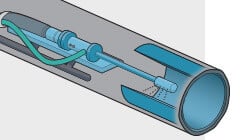

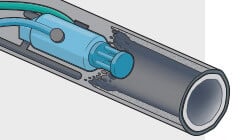

Laterals can be accessed from either end: from inside a home using a push camera or from the main line. Lateral launch crawlers are designed to travel down main lines and then launch a secondary camera into laterals.

Sometimes the number, size and type of defects observed by video inspection do not appear to justify the amount of I&I identified in the flow monitoring. In these cases, further investigation work may be needed to identify additional defects.

During CCTV, camera operators find defects and rate a sewer line's structural integrity. Sewer Scanning Evaluation Technology (SSET) gives that task to the engineer. It produces a 360-degree visual scan so that the entire surface of the pipe to be observed in flat view. The engineer can then measure the joints and cracks and check for stains and deposits.

Electrical leak location identifies pipe defects by measuring the electrical resistance of the pipe wall. Most sewer pipes are electrical insulators and have high resistance to electrical currents. A defect in the pipe that leaks water will also leak electrical current, even if there is no visible infiltration.

Acoustic, or sonar, detection uses sensors to detect vibrations and sound wave variations caused by defects and leaks (Feeney). Acoustic sensors can provide utilities with real-time verification of defects or problems.

More information on locating and detecting inflow and infiltration can be found in Working Smarter Against I/I.

The most basic way to reduce infiltration in failing pipes is to excavate a pipe and replace it. However, pipe replacement is costly and disrupts both road traffic and residential customers. For this reason, less-disruptive trenchless technologies are preferred for sewer rehab. These include (but are not limited to):

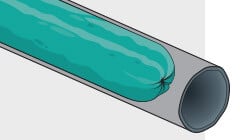

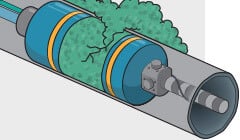

A flexible felt liner impregnated with resin is inserted into the line, generally through inversion. Hot water, steam, light or ambient temperature is used to cure the resin.

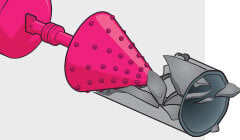

A tapered expansion head is pulled through the line, pushing the pipe wall outward until it shatters. The broken pieces are pressed into the surrounding soil and a new pipe is pulled in behind the head. Static heads are less likely to shift the surrounding soil, but dynamic heads may be used in tougher pipe or soil material.

A new liner pipe (one with an exterior diameter smaller than the interior of the existing line) is pulled in from an installation trench. The space between the old pipe and new liner pipe is filled with grout to prevent leaks and, depending on the type of grout, provide structural support.

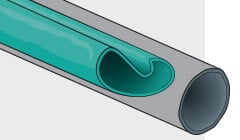

A flexible pipe is folded and inserted into the host pipe. Then it’s heated using hot water or steam to reform and fit it to the host pipe.

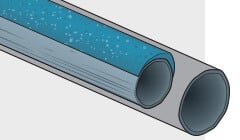

An epoxy compound is spray-blown to coat the walls of a cleaned pipe. Continuous airflow keeps the epoxy in place until it cures completely.

Pipe reaming is similar to pipe bursting: A tapered drill head is pulled through a line, breaking the existing pipe. Instead of being pushed into the surrounding soil, however, the broken pieces are suspended in fluid. The drill head then pushes the waste into a recovery pit or manhole. A new line is pulled into place behind the head.

While end-to-end methods can repair widespread defects in sewer pipe, they may be overkill for smaller cracks or flaws. That’s where spot (or point) repairs are more useful. Spot repairs target localized defects, and they are often faster, less expensive and create less disruption than end-to-end methods. When a single line has multiple defects, however, the decision between spot (point) repair and end-to-end repair requires careful consideration.

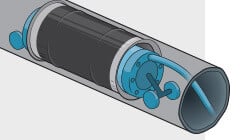

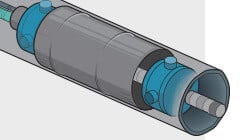

A stainless-steel sleeve with a rubber seal is inserted into a line on a balloon packer. The packer expands the sleeve, pushing the rubber against the wall to seal out infiltration. The sleeve locks in place to provide structural support.

Pressure-injecting resin or chemical grout into cracks, holes, joints and the annular gaps of lateral connections helps reduce infiltration. Resin (polyurethane or silicate) can also stabilize lines by filling voids in the surrounding soil. Most commonly, injection is performed by a packer that is pulled into location and inflated, sealing off the defect. Resin or grout is then injected to fill gaps in the pipe and any spaces behind those gaps. Chemical grout can also be sprayed into place or injected by hand.

Cement grout can be applied through injection (as with other injection methods), robotically, or manually by a worker. Cement can also be spincast, where a uniform layer is deposited on the pipe wall by a spray head as it is pulled through the pipe.

A carrier is pulled into place and expanded, pressing the deformed section of pipe outwards to make it round again. A stainless-steel clip attached to the carrier is pressed outwards to maintain the correct shape of the line.

More information on these techniques can be found in the training guide: Sewer Maintenance 101: The Quick and Dirty Guide to Sewer Inspection and Upkeep.

The financial impact of inflow and infiltration includes both treatment costs and regulatory penalties.

Treating extraneous flow is expensive. The EPA’s 2014 O&M rate for wastewater systems is $2 to $5 per thousand gallons. And one Tennessee study found that inflow and infiltration accounts for about 104,720 million gallons per year in that state−45% of the annual flow to processing plants (I/I Survey, George Kurz). Treating this extra water is estimated to cost at least $188 million statewide annually.

Communities experiencing severe I&I may also be fined by regulators. The Clean Water Act (CWA) establishes the basic structure for regulating discharges into U.S. waterways and setting standards for the wastewater industry. The cost of penalties and fines under the CWA can be greater than the cost of creating a comprehensive inspection program. In some cases, the EPA may even waive fines if system operators develop a plan to reduce I&I. Either way, failure to address I&I can have catastrophic environmental and financial consequences.

Learn more in this article: The Financial Impact of I&I.

Inflow and infiltration robs valuable capacity from treatment plants. Such capacity shortfalls can lead to damaging and costly sanitary sewer overflows (SSOs). Thirty-five percent of water entering a water treatment plant is I&I, according to the Chalmers University of Technology’s Division of Water Environment Technology. Another 35% is stormwater, and the remaining 30% is sewage. In other words, 70% of total flow into a treatment facility is water that would not need treatment had it not entered a sewer line.

Learn more in the article, What is I&I’s Impact on Water Treatment Capacity?

Read about the City of Hillsboro, Oregon and its program to combat infiltration in this customer spotlight.

Franklin Township Sewer Authority in New Jersey uses a preventative maintenance program to tackle infiltration. Its strategy includes ongoing sewer flushing, inspections and rehabilitation. These efforts have significantly reduced inflow and infiltration throughout its collection system. Learn more here.

Ready to Test Your Inflow and Infiltration Chops? Take the Sewer IQ Inflow and Infiltration Quiz